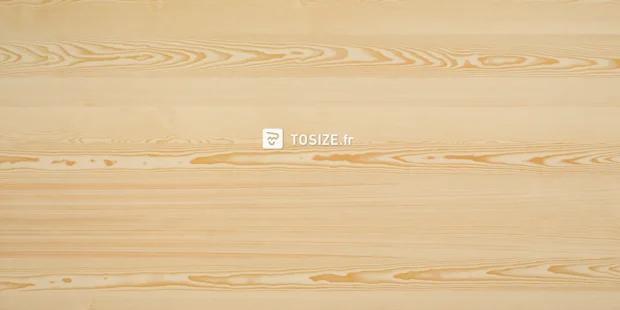

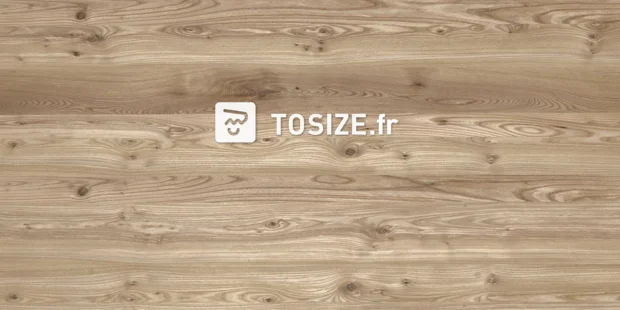

A solid wood board is a board made of wood through-and-through. A veneered board is a board material finished on the top (and bottom) side with a wooden veneer layer. A veneer top layer is a thin cut wood top layer glued or glued to a strong backing. Both panels have a beautiful look and bring warmth into your home! One of the best-known wood panels is oak; in addition, spruce is also a popular wood species.

If you are talking about veneered board material, then surely veneered MDF is one of the best-known types. Yet there are also other carriers available such as solid wood or plywood. In our range, you will find a wide selection of veneered board material.

Order veneered mdf cut to size

Order cut-to-size solid and veneered panels online

Buy cut-to-size solid wood panels or veneered panels easily online. We have different brands, designs and cutting styles available. We understand that the many options make it difficult to choose. Using our filters, you can easily find the look that suits your application. There is a suitable wood type or thickness for every job!

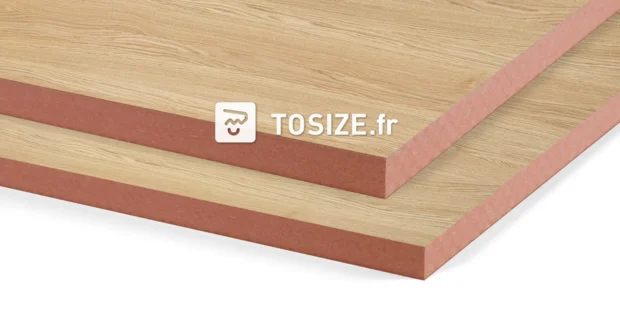

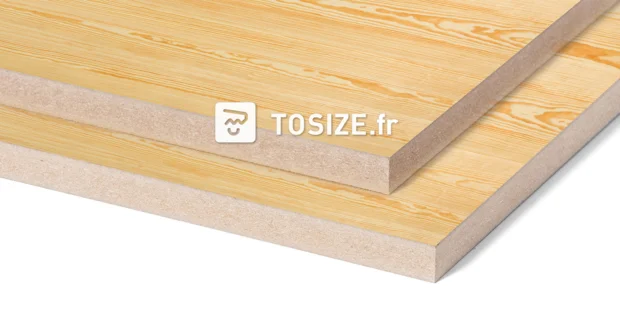

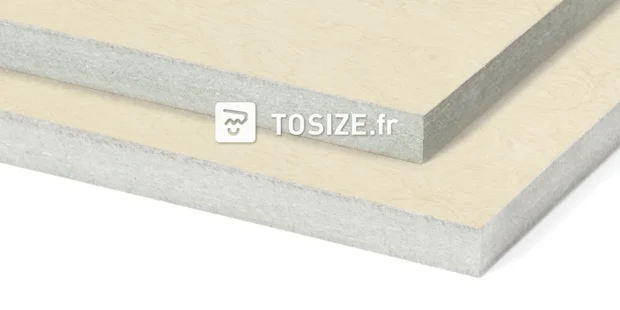

Our veneer decors feature an elegant veneer layer (from real wood). This gives the wood boards an attractive appearance and gives them a natural look. Veneered boards are structural boards, often MDF, finished with a thin, wooden top layer. This gives it the look of a solid wood panel, but the advantages of MDF. This makes the panels more practical as well as more durable than solid timber panels. This is because fibreboards consist of compressed wood chips, which is a waste product.

What is veneered board material?

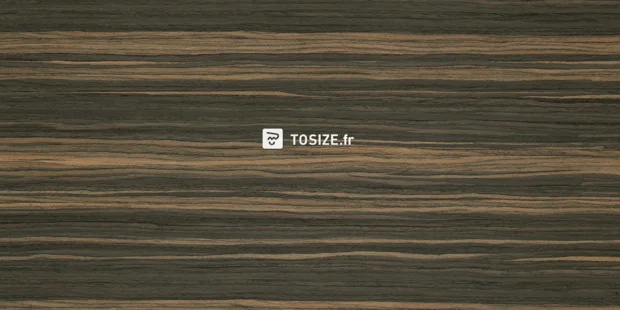

Veneered boards are boards finished with a thin wooden veneer on the top (and bottom) side. This wooden veneer is a thinly cut slice of wood that is glued or glued to a support, giving the board as a whole a solid appearance. Veneers are cut and constructed in different ways. The best-known variants are bilge, quarter-timber and coil. Depending on the wood species and cutting method, a certain look is created. You can read more about the different types of veneer below.

Veneers are ideally suited for decorative purposes due to their natural appearance: they combine the strong properties of the support with a top layer of your choice. Because the material only has a thin top layer, it is also a lot more affordable than solid board material and you still retain the real natural look and feel. However, it is important to realise that a veneer top layer, just like solid board, is real wood and therefore sensitive to UV. It is therefore important to finish veneered board materials with a lacquer or stain.

View our range of veneered sheet material here:

- MDF Altair Teak Veneer

- MDF Antares Teak Veneer

- MDF Ara Rosewood Veneer

- MDF Ash crown cut veneer

- MDF Atlas Oak Veneer

- MDF Atria Oak Veneer

- MDF Autumn Larch Veneer

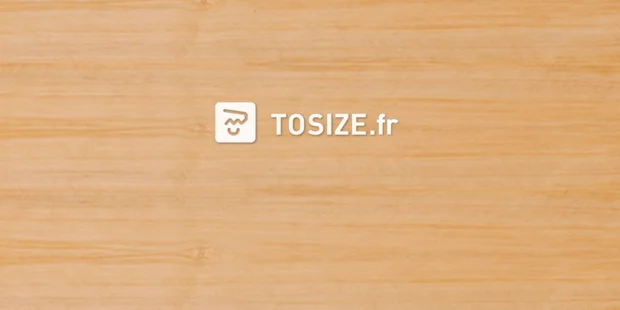

- MDF Bamboo Caramel Side Pressed Veneer

- MDF Bamboo Natural Side Pressed Veneer

- MDF Beech Steamed crown cut veneer

- MDF Black Bamboo Natural Side Pressed Veneer

- MDF Chalk Ash Veneer

- MDF Cherry crown cut veneer

- MDF Chocolate Oak Veneer

- MDF Cinnamon Triba Veneer

- MDF Clean Spruce Veneer

- MDF Corvus Ebony Veneer

- MDF Desert Oak Veneer

- MDF Dusk Frake Veneer

- MDF Frozen Walnut Veneer

- MDF Granite Walnut Veneer

- MDF Honey Pine Veneer

- MDF Hydra Birch Veneer

- MDF Ivory Oak Veneer

- MDF Lyra Oak Veneer

- MDF Mahogany crown cut veneer

- MDF Mahogany quartered-veneer

- MDF Manhattan Oak Veneer

- MDF Maple crown cut veneer

- MDF Matar Wenge Veneer

- MDF Milk Oak Veneer

- MDF Mineral Triba Veneer

- MDF Mira Wenge Veneer

- MDF Natural Oak Veneer

- MDF Oak Natural Adagio Veneer

- MDF Oak Natural Allegro Veneer

- MDF Oak Natural Vivace Veneer

- MDF Oak Quartered veneer brushed

- MDF Oak Quartered-veneered

- MDF Oak Retro Baltimore Veneer

- MDF Oak Retro Harlem Veneer

- MDF Oak Retro Hoboken Veneer

- MDF Oak Smoked Arabica Veneer

- MDF Oak Smoked Havana Veneer

- MDF Oak Smoked Robusta Veneer

- MDF Oak Veneer

- MDF Oak mix veneer

- MDF Oak mix veneer brushed

- MDF Oak mix veneer lacquered

- MDF Orion Oak Veneer

- MDF Pine Wild Veneer

- MDF Pine crown cut veneer

- MDF Polaris Pine Veneer

- MDF Rana Oak Veneer

- MDF Raven Oak Veneer

- MDF Sirius Birch Veneer

- MDF Smoked Walnut Veneer

- MDF Snow Birch Veneer

- MDF Spica Zebrano Veneer

- MDF Spring Larch Veneer

- MDF Stardust Walnut Veneer

- MDF Stone Triba Veneer

- MDF Talitha Ebony Veneer

- MDF Vela Oak Veneer

- MDF Vivid Spruce Veneer

- MDF Walnut crown cut veneer

- MDF Water-resistant Birch crown cut veneer

- MDF Water-resistant Bubinga crown cut veneer

- MDF Water-resistant Bubinga mix veneer

- MDF Water-resistant Oak Dose Veneered

- MDF Water-resistant Oak Quartered Veneered

- MDF Water-resistant Oak mix veneer

- MDF Western Red Cedar mix veneer

- MDF Winter Larch Veneer

- Plywood Oak Crown Cut Veneer

Order affordable sheet material with a wooden look made to measure

When looking for finished board material, you generally end up in two categories: melaminated board material and veneered board material. As a carrier, or base, MDF, chipboard or another strong board is often chosen. The difference between these carriers is generally minimal. Are you looking for a specific texture, or colour? Then go for your favourite top layer and don't let the material's carrier influence you.

Veneered panels

Because veneered material is glued to a support, it inherits its strong basic properties, so veneered board material does not warp compared to solid board material and the board material is easy to assemble and process. However, it is still real wood, which is why the material remains sensitive to UV radiation, which can cause discolouration. It is therefore important to protect veneered board material with, for example, lacquer, oil, stain or wax.

When you cut veneered board material to size, you will see that only the top and bottom layers of veneer have been applied. On the sides, you will see the backing material (usually MDF). To finish these sides nicely, there is veneer tape. This is available in the same type of wood as the top layer, to create a nice whole after finishing the edges.

Veneered board material is easier to process yourself than melaminated board material, because the veneer layer splinters less easily. Want to be sure that the cut edges look neat? Then have the material professionally cut to size by us!

The advantages of veneered material are:

- Natural product, each panel is unique

- Durable compared to solid board material

- Indistinguishable from solid wood

- Beautiful, warm and natural look

Veneered MDF or solid furniture panels?

Veneered MDF

We are all familiar with the properties of MDF: a compressed fibreboard. As with chipboard, the quality of the MDF depends on the pressing pressure and pressing time. We only cut high-quality MDF. Whereas chipboard used to be the standard backing for melaminated furniture panels, MDF is gaining ground due to its strong, stable and high-quality properties. Due to its homogeneous structure, it is less likely to blunt your sawing and drilling equipment and is easy to assemble. Are you looking for veneered material? Then the standard carrier is MDF or, traditionally, solid panels. Because veneers are more fragile than melaminated material, MDF is always chosen as the carrier for these top layers.

Solid panels

Are you looking for furniture panels with a wooden look? Then you may also end up with solid panels. Or solid panels with a veneer top layer. In the wood industry, solid is often used as a catch-all term. A truly solid panel, consisting of a single piece, is very expensive. In addition, there is scarcity in the industry, so new wooden panels are assembled in a creative way. This keeps the material affordable, accessible and creates the same look and feel as a solid panel. Wood panels with a solid core are one of the oldest types of veneer panels. Wooden slats are used for the core and the top layer is then finished with a veneer. The quality and price strongly depend on the visual quality of the veneer, the thickness of the top layer and, whether it is one- or two-sided finished.

Decorative chipboard

Finally, we would like to briefly mention furniture boards.This is not a veneer panel, but a chipboard with a melamine (plastic) top layer. This panel material is completely finished and does not need to be treated like solid wood panels and veneers do. Melaminated panels are produced in many colours and versions and are nowadays almost indistinguishable from an extra natural look-and-feel. Melamine-faced panels have a number of important properties:

- It is ecologically a sustainable choice

- It is relatively cheap

- It is a light a versatile material

- It is easy to saw and screw.

- It does not require finishing

Want to make it easy on yourself? Then choose melaminated board material instead of veneer.

The properties of decorative furniture panels

Above, you have read about the difference between solid and veneer. The different types of supports have also been covered. But besides these properties, there are also some practical properties that can apply to your DIY projects.

Furniture panels

The most common variant of available furniture panels is with a chipboard or MDF backing. Are you curious about the properties of that panel material? Our tip: Then read more about the properties of the carrier. That way, you can quickly find out whether the board material is suitable for your next DIY project.

Veneer panels with water-resistant properties

If you see the type V313 or the term water-resistant passing by the product, then the core of the carrier is water-resistant. The gluing, pressing pressure and pressing time of the composition of fibreboards add extra water-resistant properties to the board material. However, always bear in mind that the top layer is not necessarily water-resistant. Curious about the properties? Check out the properties of Damp-proof MDF or Moisture Proof chipboard.

Veneering and marking

Veneer panels can be ordered in several varieties and thicknesses and with a wide variety of textures. Don't be put off by the many brand names such as Nørdus, Infinite Wood, Querkus or other major brands. The decors are similar in colour, texture and quality. We have several brands and only supply high-quality veneer panels with a unique look.

Read more about the different brands we offer here.

Veneered MDF as an interior application

Veneered MDF is widely used for making furniture. It is a versatile product so it can be used for many purposes. Think of (partition) walls, wall cladding, furniture applications, doors and more. With the various decors and textures available, there is a suitable board material for every job.

DIY projects with furniture panels

Need inspiration or just curious about what you can achieve with veneered board material? Then take a look at our DIY and interior blog. Many others preceded you by ordering made-to-measure MDF. Perhaps your dream furniture is already among them and you can adopt the shopping list in no time.

Alternatives to furniture panels

Is veneered board material not what you are looking for after all? Check out our whole range of sheet material; everything can be cut or milled to the millimetre and find the ideal type of wood for your next project.