HPL stands for High Pressure Laminate. HPL is pressed sheet material that is weather- and waterproof. This thin sheet material is ideal for decorative applications. HPL is a term with two meanings: There are HPL top layers and there are HPL boards. An HPL top layer is a hard, thin layer glued to another type of backing such as MDF or plywood. An HPL board is a sheet material that is fully pressed.

Order sheet material with an HPL top layer made to measure

Order cut-to-size sheet materials with an HPL top layer online

Buy cut-to-size sheet materials with an HPL top layer easily online. We have several brands and designs available. We understand that the many options make it difficult to choose. Using our filters, you can easily find the look that suits your application. There is a suitable wood species or thickness for every job!

HPL: what is it?

HPL stands for High Pressure Laminate. HPL is pressed sheet material that is weather- and waterproof. This thin sheet material is ideal for decorative applications. HPL is a term with two meanings: There are HPL top layers and there are HPL panels. An HPL top layer is a hard, thin layer glued to another type of backing such as MDF or plywood. An HPL board is a sheet material that is fully pressed.

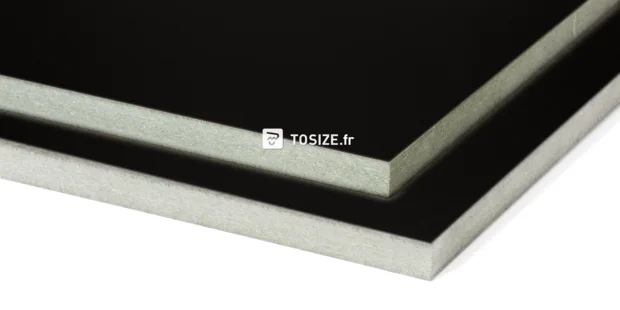

The construction of HPL panels

HPL sheets are made by impregnating a core layer of paper and wood fibres with phenolic resin. This substance is compressed under high pressure and temperature. This makes the boards or top layer smooth, very strong and dimensionally stable. This sheet material is also compared to plastic. The core layer of the HPL sheets are then coated with a protective, coloured top layer at the top and bottom. This makes the boards generally scratch- and impact-resistant and protected from sunlight and moisture.

Properties of HPL

HPL is a well-known term and means you have a high-quality material in mind. The products have a long lifespan due to their hard and impermeable core. HPL is low-maintenance, hygienic and retains minimal dirt. The panels are widely applicable and available in many different shapes and colours.

HPL or melamine

Melaminated board material as well as board material with an HPL top layer no longer needs to be finished. Are you going to use board material for interior applications? Then both panels are a good option. High-pressure laminate is suitable for decorative, yet hard-wearing, long-life applications. Depending on the brand and production method unique properties, you will find more information about this per product. The main difference between the two is that HPL generally offers a smaller range than melamine-faced board material. Need to make a choice for your project? Then look mainly at the properties of the carrier. For instance, HPL is more often used on a support with moisture-resistant properties and is therefore more popular for outdoor use.

Types of HPL

Sheet material with an HPL top layer can have different types of carriers. In our range, you will mainly find HPL glued to plywood, but other substrates are also available such as MDF or chipboard. There are several suppliers of HPL top layers. Brand names such as UNILIN, Pfleiderer, Abet, Leitopal and Formica® are well-known authorities when you are looking for HPL Sheets. The different lines within the brands give the top layers unique properties. Read more about them at the products themselves!

View our range of sheet material with an HPL top layer here :

- MDF HPL 0032 Bianco Kos

- MDF HPL 0720 Nero Ingo

- MDF HPL U11026 HG Crystal white

- MDF HPL U11027 HG Ice white

- MDF Water-resistant HPL 025 CST Front white

- MDF Water-resistant HPL 113 CST Elegant black

- MDF Water-resistant HPL 625 CST Silicon

- MDF Water-resistant HPL U128 CST Stone grey

- MDF Water-resistant HPL U129 CST Shadow

- MDF Water-resistant HPL U172 CST Ivory

- MDF Water-resistant HPL U823 CST City grey

- MDF Water-resistant HPL U824 CST Twilight grey

- MDF Water-resistant HPL UD26 CST Elephant grey

- MDF Water-resistant HPL UD81 CST Quartz

- MDF Water-resistant HPL WE28 BST Everest white

- MDF Water-resistant HPL WE28 CST Everest white

- MDF Water-resistant HPL WE31 BST Lily white

- MDF Water-resistant HPL WE31 CST Lily white

- Plywood Birch HPL 0720 Nero Ingo

- Plywood Birch HPL W10400 VV Opaque White

- Plywood Birch HPL white

- Plywood CPL U129 TST Shadow

- Plywood HPL F6463 Sheer White Shell

- Plywood HPL F6464 Shell New White

- Plywood HPL F6466 Shell Silk Grey

- Plywood HPL F6467 Shell Granite Grey

- Plywood HPL F6468 Shell Jet Black

- Plywood HPL F6632 Shell Pewter Grey

- Plywood Birch HPL U12000 SD Vulcanic Black

- Plywood Birch HPL W10400 SD Opaque White

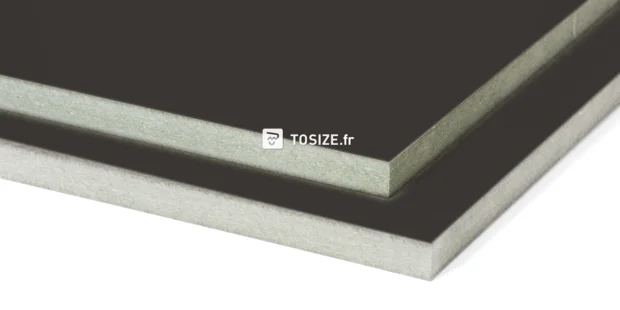

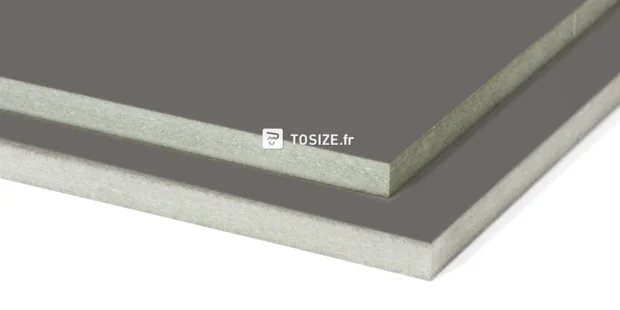

Different colours and top coats of HPL

HPL is available in uni colours, fantasy decors as well as wood textures. The possibilities are endless! Using our filters, you can easily find the look that suits your application. There is a suitable wood species or thickness for every job!

HPL panels and moisture

As the top layers are compressed under high pressure, weather conditions and temperature differences have minimal influence on these top layers. This makes this panel material extremely suitable for decorative outdoor applications. Note that the properties of the carrier also contribute to the choice of panel.

Available thicknesses of HPL

Veneer panels can be ordered in several varieties and thicknesses and with a wide variety of textures. Do not be put off by the many brand names. The decors are similar in colour, structure and quality to melamine faced panels. Is your colour/thickness combination not among them? Then take a look at our melamine range.

Read more about the different brands we offer here

Common applications of HPL

Panels with an HPL top layer are used in wall coverings, furniture, worktops and doors. But think also of table tops, walls or other interior applications. The possibilities are endless! Thanks to their hygienic surface, panel materials with an HPL top layer are also extremely suitable in public buildings such as healthcare, offices or education.

DIY tips for fitting and finishing HPL

HPL is available in many colours, making painting unnecessary. Panels with an HPL top layer are more difficult to process than the average (wooden) panel materials. We strongly advise against cutting HPL-coated panels to size with a handsaw. It is best worked with a jigsaw or circular saw.

Alternatives to HPL panels

Can't find a suitable panel with an HPL top layer for your next DIY job because the colour you're looking for is not available? Then also check out our gemelamineerde panelen or go for { 'MDF'|trans}}, which you can easily paint.