- TOSIZE.fr

- Wood and sheet material

- Plywood

Plywood Marine fire retardant

Product information

- Ontvlamt minder snel

- Vermindert verspreiding van vlammen

- Sterk en licht materiaal

- Rustige, natuurlijke uitstraling

- Buigt niet door onder zware belasting

- Gronden voor afwerking aan te raden

Description

Multiplex okoumé brandvertragend is de multiplex variant die bestand is tegen vocht én behandeld is met speciale brandvertragende chemicaliën die zeer langzaam ontbranden. Multiplex is opgebouwd uit verschillende fineerlagen. Deze lagen worden kruisling op elkaar verlijmd. Dit leidt tot een stabiele plaat. Brandvertragend multiplex wordt niet beschouwd als onbrandbaar, maar het kan vaak worden gebruikt in plaats van onbrandbare materialen in bepaalde situaties.

Best alternatives for this product:

How convenient is that

Product information

- Ontvlamt minder snel

- Vermindert verspreiding van vlammen

- Sterk en licht materiaal

- Rustige, natuurlijke uitstraling

- Buigt niet door onder zware belasting

- Gronden voor afwerking aan te raden

Description

Multiplex okoumé brandvertragend is de multiplex variant die bestand is tegen vocht én behandeld is met speciale brandvertragende chemicaliën die zeer langzaam ontbranden. Multiplex is opgebouwd uit verschillende fineerlagen. Deze lagen worden kruisling op elkaar verlijmd. Dit leidt tot een stabiele plaat. Brandvertragend multiplex wordt niet beschouwd als onbrandbaar, maar het kan vaak worden gebruikt in plaats van onbrandbare materialen in bepaalde situaties.

Product properties

Applications

- Jachtbouw

- Dakconstructies

- Kozijnen

- Draagconstructies

- Buitenmuren

- Ombouw

Order Okoumé fire-retardant plywood panels online

Order your cut plywood okoumé fire-retardant easily online. You can have Plywood cut to size or milled into various shapes. The most popular form is a rectangle, but we also cut circles, ovals, hexagons or even parallelograms to size. Do you want your do-it-yourself project neatly finished? Then choose one of the available (edge) finishes.

Okoume plywood fire retardant: what is it?

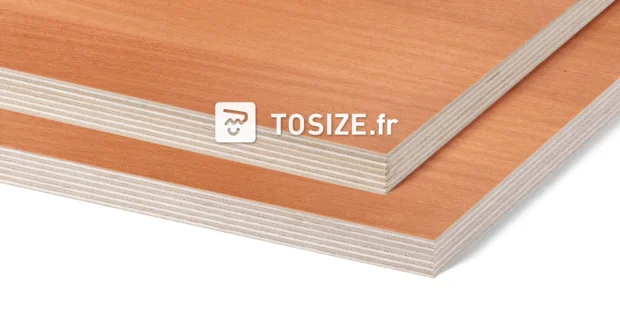

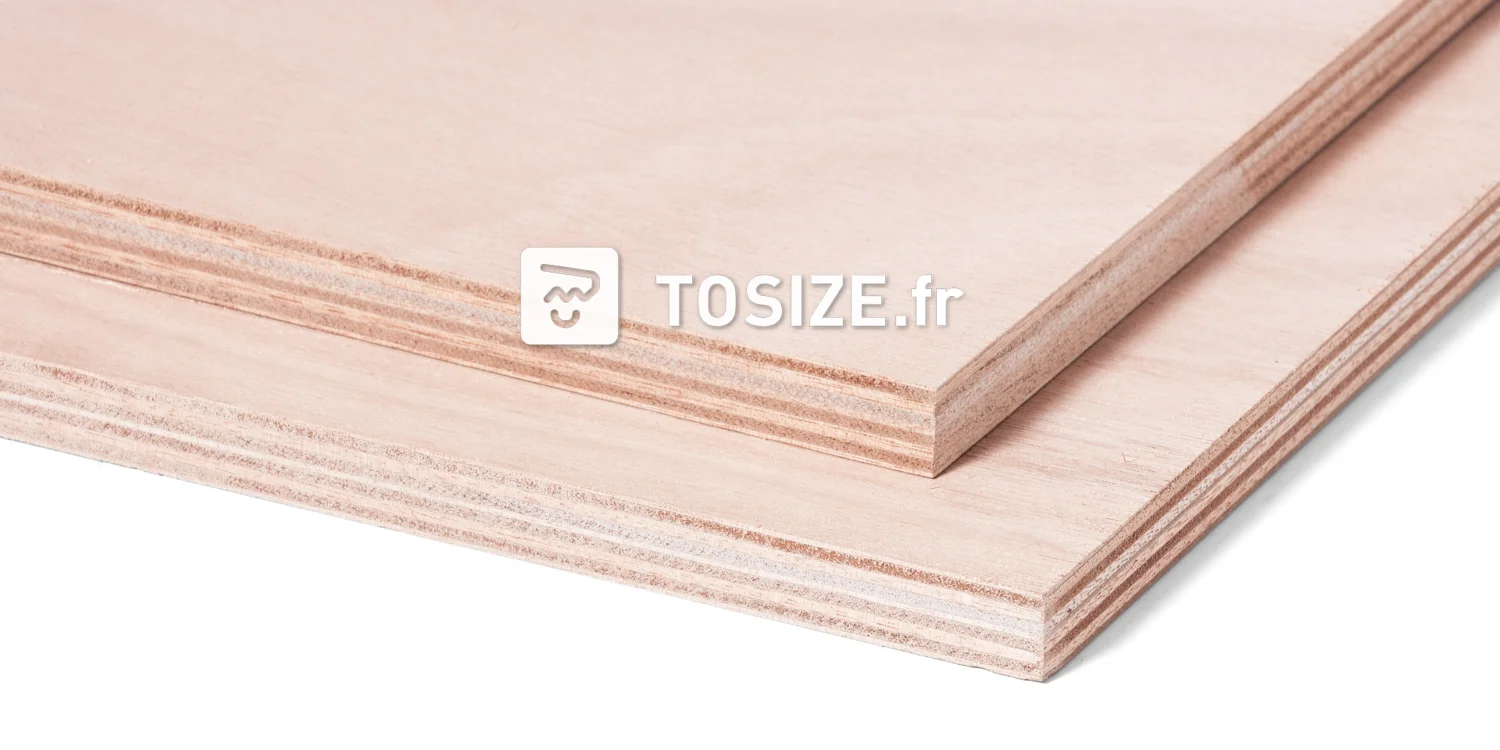

Okoume fire-retardant plywood is the plywood variant which is resistant to moisture and treated with special fire-retardant chemicals that ignite very slowly. Plywood is made up of different layers of veneer. These layers are glued crosswise to each other. This results in a stable board. The sheets have an attractive edge that is well suited to visible work. Our plywood panels are suitable for horizontal applications, such as table tops and window sills. It is important to fix plywood panels in place. If you do not do this, the chance of warping is very high.

This okoumé comes mainly from Gabon, located in Central Africa, where the logging is under strict control of the government. These panels are glued with a waterproof glue, just like plywood birch. Okoumé has a better resistance to moisture than Birch, making this plywood variant suitable for outdoor applications. Are you going to use this panel outside or in humid conditions? Then finish it off with special protective agents. But you can also choose the panel for its beautiful pink-red colour with coarse flames and the fact that it is easy to process. This board material has a fine and subtle structure, making it a very popular wood type in yacht building.

Fire retardant properties

These panels are specially treated with fire-retardant chemicals which makes them much less flammable than traditional plywood. This means that this panel material is more resistant to fire ignition and prevents the spread of fire should a fire develop around the panel. In the event of a fire, the flames are less likely to spread and slow down the combustion. Fire retardant plywood is not considered to be non-combustible, but it can often be used instead of non-combustible materials in certain situations.

The protective layer is applied in such a way that it has no effect on the wood structure of the okoumé panels. It therefore simply preserves its natural and attractive wood colour.

Plywood quality B/BB

The quality of plywood surface layers is indicated by letter combinations and refers to the visual assessment of plywood wood. There is a letter designation for the visible side (top) and one for the reverse side (bottom). It refers to the quality of the deck veneer, the quality of the gluing, for example, is indicated differently. Read more about all visible qualities here.

This board material has visible side B/BB. The top side has visual quality B, the underside visual quality BB. A plywood panel with face quality B/BB usually has an acceptable visual quality, but does show some imperfections. On the front (the "B" side), colour variations, small knots, repairs and other irregularities may occur, albeit to a limited extent. The reverse side (the "BB" side) may contain more imperfections, such as large knots, repairs and colour variations.

Because of its slightly lower visual quality, plywood with the visibility grade B/BB is often used in applications where aesthetics are not the highest priority. It is used for structural purposes, internal cladding, furniture construction and other applications where the visible surface is less important.

It is important to note that visibility grades can vary depending on local standards and specifications. When purchasing plywood, it is advisable to consult the specific ratings and standards of the manufacturer or supplier to ensure that the wood meets the requirements for the intended application.

In general, plywood with sight grade B/BB offers reasonable visual quality for applications where aesthetics are not a top priority. It combines functional properties with an acceptable surface that meets the basic requirements for many construction and timber projects.

Available thicknesses of okoumé fire-retardant plywood

You can order plywood in different thicknesses. You can easily specify your desired thickness during the ordering process. This way, you can be sure that the sheet material meets your requirements: both the format and the thickness of the material. The following thickness(es) are available: .

Processing of okoumé plywood fire-retardant sheets

Okoumé plywood is a hardboard material. It is easy to work with, if you have sharp tools. For drilling holes, we recommend a wood drill with a centre point. Pre-drilling is also recommended for this type of panel. Be aware that okoumé can discolour over time, so finish with a (clear) varnish, stain or paint. Use an edge sealer to finish the edges of plywood, this will prevent the varnish or stain from penetrating into the panel material, which may lead to the separation of the veneer layers. Are you going to use okoumé outside? Then it is important to seal the edges with an edge sealer. In order to be able to enjoy the project outside for a long time, this panel material still needs protection against damp weather conditions.

Specific applications of okoumé fire-retardant plywood

Okoumé fire-retardant plywood is very suitable for projects such as dormers and wall cladding. Okoume plywood is also widely used in the yacht building industry. This fire-retardant variant is particularly interesting when insurance companies expect a certain degree of fire safety.

Alternatives for okoumé fire-retardant plywood

Is okoumé plywood fire-retardant not the right type of wood for your job or are you looking for a plywood variant that is easy to treat with a varnish or paint and suitable for outdoor use? Then go for multiplex okoumé watervast gegrond. Or check out our other plywood panels below: