Made to measure wooden table legs

Table legs are the finishing touch to your dining table! They give your table the desired character. With the shape and thickness of the legs you can determine what look you give your table. Are you going for modern, industrial, classic, retro or rural? Let yourself be inspired for an amazing result! Whether you make the table legs yourself or not; a result to be proud of!

Table leg shapes made to measure

The shape of the table's base determines the look of the whole. Therefore, take a good look at the desired style of the table and choose the right table legs to go with it. A great advantage of making your own table legs is that your table is completely unique and you can match the tabletop to the shape and thickness of the legs very well. Have you come up with a nice design for the whole thing? Then have the material cut into the right shape and dimensions by TOSIZE.fr! An edge trim can be a subtle detail to finish off your table legs. We can do that for you, too, without any trouble.

This is how it works

In short, you come up with a great design, decide on the dimensions, materials and simply place an order with TOSIZE.fr. TOSIZE.fr takes care of the sawing to the millimetre and effortlessly cuts the shapes and possible finishes. We also deliver the material to your home, which means no hassle with transport. Handy, isn't it? Now let's have a look at the possible shapes of your custom-made table legs.

Sawing in mitre

With TOSIZE.fr you can have the edges mitred in the number of degrees required for your table legs. To create a 90 degree angle, you can have two parts mitred with a 45 degree angle. Do you have a design of which the angle is not 90 degrees? Calculate the desired angle, indicate this during the ordering process and let us saw it into a mitre. You can mitre the top or bottom or both sides of the board. And there are more edge finishes you can have cut by us. For a complete overview, see our website at edge finishes.

O-shaped table legs

The O-shape is the simplest form to give your table top a solid base. It is a straightforward shape and therefore easy to make a construction that can carry the weight of the tabletop. This shape fits well with all styles of living, depending on how coarse you make the legs. For example, if you make the legs square and paint them black, it fits perfectly in a retro interior. If you make them narrower and paint them white, then it is perfectly suited to a modern home. So you can play with this to get the best result.

You can literally make an O-shape, but you can also make the top or the bottom decrease or increase as shown in the sketches below. It gives a playful twist! It is also a surprising choice to add an extra beam or upright in the 'O'. How? It could be a transverse beam, a grid of vertical strips or anything else that makes your table legs unique.

U-shaped table legs

With a U-shaped table leg, it is important to think carefully about the construction. The "U" is not solid in itself and even when the tabletop is attached it can still wobble. For extra sturdiness, place a crossbar between the two legs!

A-shaped table legs

If you raise the crossbar at the bottom of the O-shape slightly, an A-shape is created. This makes the leg look a little less chunky, because the table leg looks more spacious. You can of course play with the height of the crossbar. Choose the height you like!

X-shaped table legs

A table with an X-shaped base is currently a common sight in home furnishing shops and magazines. It is a popular shape, but not so easy to make yourself. Although this of course depends on your knowledge of the job. Are you going for a table with an 'X' shaped base? Nice work!

V-shaped table legs

Thanks to the edge processing we offer: sawing in mitre, it is also possible to make a V-shaped table leg. It requires solid construction! A V-shaped table leg is generally a bit coarser due to the thicker legs in order to get a solid construction.

Own design

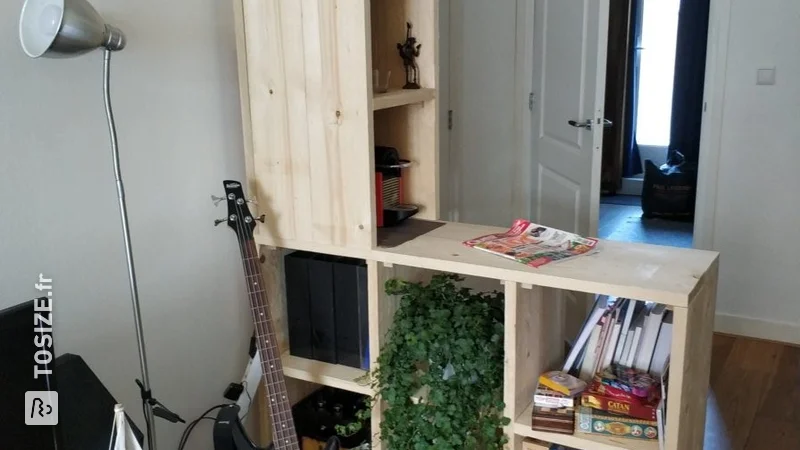

Of course, you can also come up with your own shape for your custom-made wooden table legs! Then you can be sure of unique table legs! The letter shapes described above are often made of solid beams or multiple layers of sheet material on top of each other. You can also choose to use sheet material that is officially intended for making constructions and therefore very strong. For example, Underlayment Finnish Spruce, Plywood or OSB. For example, attach four legs of two slats cut at right angles to each other as a rectangle with a bevelled long edge. Want to know more about the shapes we can cut? Click here for the shapes we can cut.

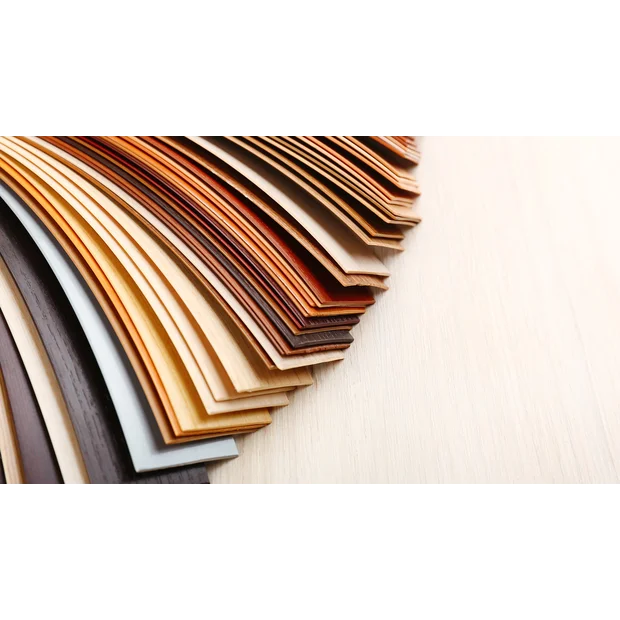

Choice of material for table legs

At TOSIZE.fr you can order many different types of wood and board material. From scaffolding wood to furniture panels and from underlayment to OSB. Take a look and be inspired. View our current range here. And are you looking for material that is not in our range? Then keep an eye on our website, because we are constantly developing!

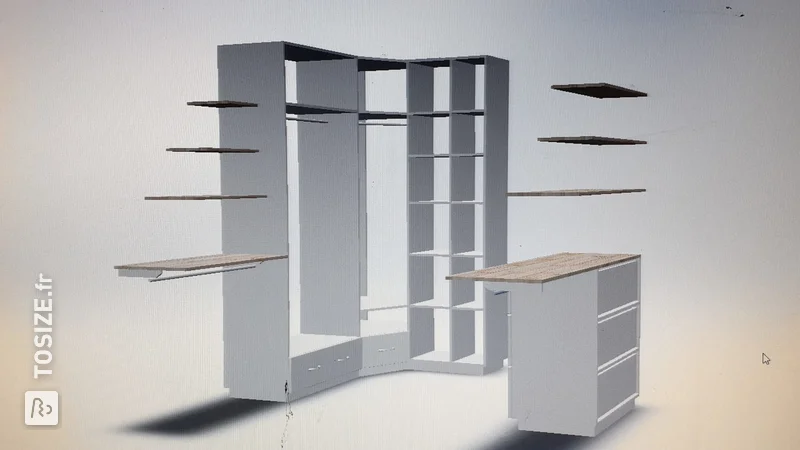

Create a design

With all the above information in your pocket, you can start sketching the most suitable table legs. The great advantage of making a sketch is that you also have to think about the construction and dimensions. It gives a complete picture of your idea! And with that detailed design in your pocket, you can order the material in no time using our simple ordering process. If necessary, add the required accessories directly. Then you can start building your job right away.

Also check out these similar DIY tips